By Lisette Hilton – Dermatology Times

Smart skin that acts like the real thing

Using household items, engineers in Saudi Arabia have created a recyclable paper-based smart skin, capable of detecting temperature, humidity, pH, pressure, touch, flow, motion and proximity at 13 cm, according to a new study in Advanced Materials Technologies.

The study’s senior and corresponding author Muhammad Mustafa Hussain, Ph.D., says this is the first time a singular platform shows multi-sensory functionalities close to that of natural skin.

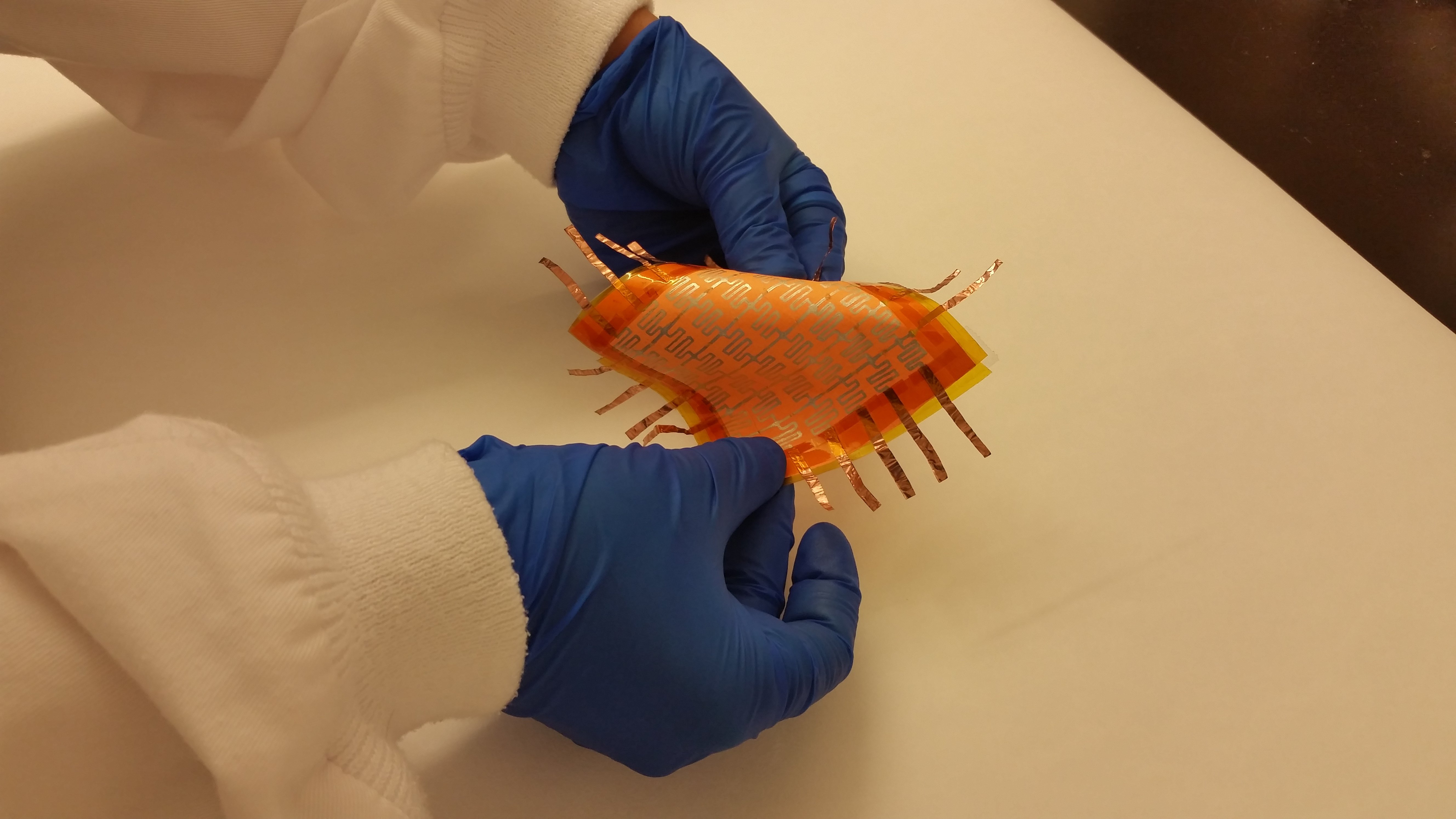

A model of a paper skin with an array of 6 x 6 sensors which can sense pressure, proximity, temperature, strain, pH, flow and humidity. This sensor array is made with recyclable household materials.

Photo: Muhammad Mustafa Hussain, Ph.D.

Dr. Hussain, associate professor of the electrical engineering, King Abdullah University of Science and Technology (KAUST) in Thuwal, Saudi Arabia, tells Dermatology Times that the development of artificial skin is an important goal in skin care, especially for wounded war, vehicle injury and acid victims. Since skin is mesoporous and covers a larger surface area, the artificial technology needs not only necessary sensory capabilities, but also should be made from affordable materials and by appropriate electronic device engineering to integrate sensory functionalities.

“In that sense, our demonstration shows the proper integration strategy for multi-sensory skin type platform creation, which can sense simultaneously and in an affordable manner,” Dr. Hussain says. “I believe that there will be more advent in this area based on our work and, soon enough, artificial skin mimicking natural skin will be developed, which can be connected to our neural system. Dermatologists can guide us (engineers) to innovate and to develop right ‘skin.’”

They made the smart skin from recyclable materials, including aluminum foil, carbon paper, sponge and more—materials manufactured cheaply and at high volumes, according to Dr. Hussain.

“The integrated strategy we have developed can make an absolutely manufactureable version [of the smart skin] in two years,” Dr. Hussain says. “A major challenge would be neural connectivity …. We also envision and have been working on adding capabilities like drug delivery in this ‘skin’ which can personalize medication.”

Recent Comments